Is Rosco Foamcoat Flame Retardant? Safety & Compliance Guide

In brief: Foamcoat is inherently flame retardant and much safer than raw foam or many solvent-based hard coats. This page explains how it behaves around flame and why it’s widely used in theatres, schools, film studios and public installations.

When you are building scenery, props, or displays out of foam, safety is not optional. Many venues, theatres, schools, and public spaces require flame-retardant materials, especially when foam is involved. Rosco Foamcoat was designed with that in mind.

This guide explains how Rosco Foamcoat behaves around flame, why it is a safer choice than many solvent-based hard coats, and how scenic artists use it to help meet safety and compliance needs.

Is Rosco Foamcoat Flame Retardant?

Yes. Rosco Foamcoat is inherently flame-retardant. That means the coating itself is formulated to resist ignition and to help slow the spread of flame if exposed to a fire source.

While no single product can guarantee full compliance for every venue or code, using a flame-retardant hard coat over otherwise flammable foam is an important step in building safer scenic elements.

Why Flame Retardancy Matters on Foam

Raw foam is typically very flammable. Left uncoated, it can:

- Ignite quickly

- Drip or melt when exposed to flame

- Release the hazardous smoke

- Fail basic flame tests required by venues

Foamcoat provides a protective, flame-retardant shell over XPS, EPS, and pink foam. This helps:

- Reduce ignition risk at the surface

- Slow down the flame spread

- Support compliance efforts for scenic builds

It is especially relevant in theatres, schools, cinemas, theme environments, trade show booths, and seasonal displays inside public venues.

Foamcoat vs Solvent-Based Hard Coats

Many traditional foam hard coats use solvent-based or two-part resin systems. These can:

- Release strong fumes during application

- Require strict ventilation, PPE, and handling procedures

- Be more brittle once cured

- It will be harder to sand and work once set

Foamcoat is different:

- Water-based and non-toxic during normal use

- Inherently flame-retardant

- Workshop friendly for schools, community theatres, and fabrication spaces

- Carvable and sandable after curing

This balance of safety, workability, and flame performance is why many scenic shops prefer Foamcoat over more aggressive resin systems.

Foamcoat Technical Specs (Quick Reference)

- Type: Water-based, non-toxic, flame-retardant hard coating

- Finish: Off-white matte

- Coverage: ~150 sq. ft. per gallon (12–16 m²)

- Dry Time: 2–8 hours between coats

- Full Cure: ~24 hours

- Application: Brush, roll, or hopper spray gun

- Workability: Sandable & carvable after curing

- Compatibility: Works with Rosco scenic paints & most acrylics

- Packaging: 1 Gallon (3.79 L)

Looking for deeper details? You can see the full technical specifications and product information on the Foamcoat product page.

Using Foamcoat in Theatres, Schools & Public Spaces

Foamcoat is widely used in environments where you need both durability and sensible safety practices:

- Theatres and performing arts centres

- Film and TV studios

- School drama departments and auditoriums

- Museums and exhibitions

- Theme environments and attractions

- Events and corporate displays

In many of these spaces, uncoated foam is simply not acceptable. Foamcoat gives designers and builders a professional way to hard-coat foam while supporting the fire safety expectations of the venue.

Real-World Safety-Focused Use Cases

Some examples of how Foamcoat has been used where safety and durability both matter:

- Haunted attractions and Halloween installations, Scenic teams have used Foamcoat on foam tombstones, facades, and set pieces that are exposed to fog, lighting, and large crowds. Flame retardancy was essential alongside weather resistance.

- Museum sculptures and public art, Foamcoat has been applied to sculpted foam forms installed in public spaces where visitors may touch or lean on the pieces. The hard coat provides both impact resistance and improved flame behaviour compared to bare foam.

- School and community theatre sets Foamcoat lets drama departments build ambitious foam scenery in a safer way than leaving foam raw or relying on harsh solvent systems.

In all of these scenarios, Foamcoat helps balance creative freedom with sensible safety choices.

Application and Thickness for Best Performance

For both durability and flame performance, good application practice matters:

- Apply at least 1–2 coats for basic protection

- Use 2–4 coats on high-traffic or high-impact areas

- Allow each coat to dry before applying the next

- Let the piece cure for around 24 hours before use

Thicker, well-cured applications will always perform better than a single thin, rushed coat.

See the step-by-step Foamcoat application guide

Combining Foamcoat With Other Safety Measures

Foamcoat is one part of an overall safety strategy. For many productions, additional steps may include:

- Using flame-retardant fabrics and materials wherever possible

- Following venue fire regulations and approval processes

- Pairing Foamcoat with flame-retardant scenic paints

- Ensuring exits, extinguishers, and emergency plans are in place

Foamcoat supports these efforts by addressing one of the key risk areas: exposed, unprotected foam.

Is Foamcoat Safe to Use in the Workshop?

Foamcoat is water-based and non-toxic during normal use, which makes it much more pleasant to work with than many industrial hard coats.

- No strong solvent odours under normal conditions

- Easy soap-and-water cleanup while wet

- Suitable for many school and community environments

As with all coatings, normal sensible precautions still apply (good ventilation, avoiding ingestion, basic PPE as required).

Need Outdoor Durability As Well?

Foamcoat is not only flame retardant, but it is also water-resistant when cured, making it effective for many outdoor scenic and display uses.

Read the outdoor and water resistance guide

Want to Know More About Foamcoat Itself?

If you are new to Foamcoat and want a full overview of what it is, what it sticks to and how professionals use it:

What Is Rosco Foamcoat? Full Breakdown

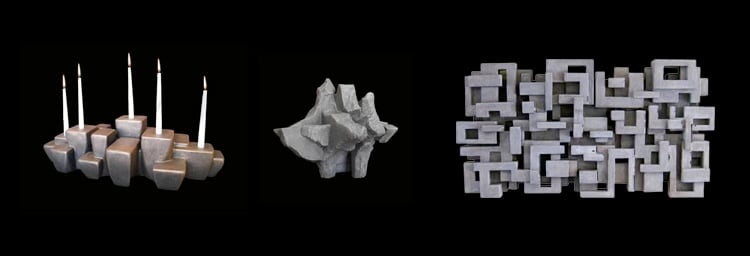

Foamcoat in Real Projects: Case Studies & Inspiration

If you’d like to see what Rosco Foamcoat can do in the real world, here are a few projects from the Rosco Spectrum blog that show it in action on Halloween displays, sculptures, and stage props.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Image & project courtesy of Rosco Spectrum.

Want to Learn More About Foamcoat?

If you’d like full specifications, SDS, application notes, or packaging details, you can view everything on the Foamcoat product page.